Stellantis is taking a bold step forward. Through groundbreaking battery technology, the global automaker aims to make electric vehicles (EVs) not only more powerful but significantly more affordable.

Affordable EVs Through Lithium-Sulfur Technology

Global automotive leader Stellantis, parent to brands like Opel, Peugeot, and Fiat, has set an ambitious goal: to develop more efficient and cost-effective EV batteries in partnership with U.S.-based battery manufacturer Zeta Energy. These next-gen batteries, based on lithium-sulfur technology, could trigger a pricing breakthrough in the EV market.

Transforming Waste into Power

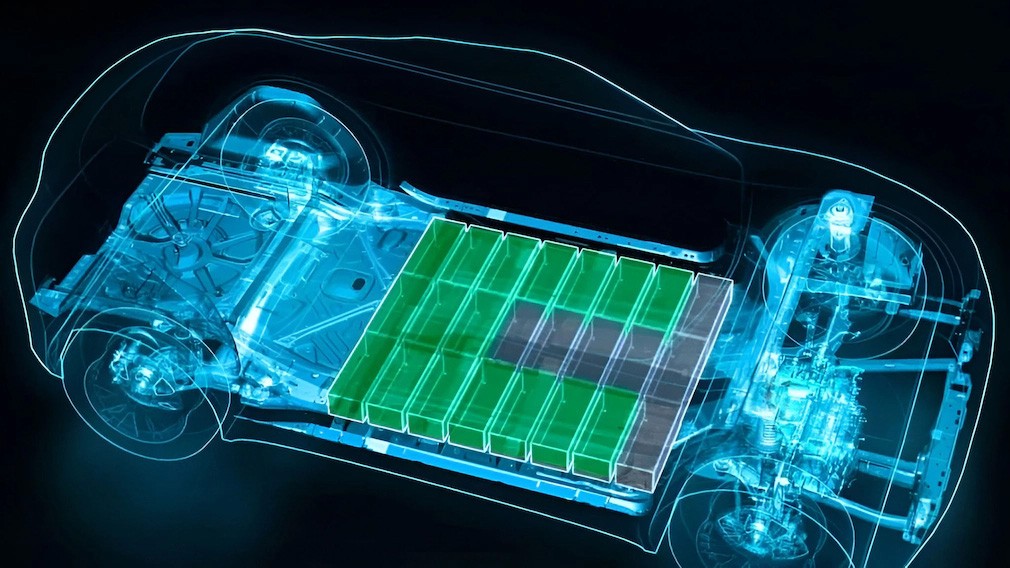

Starting from 2030, Stellantis vehicles will be equipped with lithium-sulfur batteries, achieved primarily by converting waste materials into energy sources. Unlike today’s lithium-ion batteries, which rely on expensive and sometimes scarce materials like cobalt, graphite, manganese, and nickel, Stellantis’s new batteries will utilize unrefined sulfur and methane. This innovative approach will reduce production costs to half the price per kilowatt-hour of current battery solutions.

This breakthrough is expected to ensure stable and shorter supply chains, ultimately benefiting customers through lower EV prices. Notably, since battery expenses currently account for about one-third of an EV’s cost, this advancement could significantly lower the final price consumers pay.

Enhanced Performance with Reduced Weight

While affordability is crucial, Stellantis’s lithium-sulfur batteries won’t compromise on performance. The new technology offers superior gravimetric energy density, meaning more energy in a lighter package. Moreover, it boasts volumetric density comparable to existing lithium-ion batteries, resulting in extended driving ranges.

Additionally, these batteries have the potential to reduce EV charging times by up to 50%, addressing one of the major pain points of current electric cars. Drivers will enjoy both a longer range and faster charging—key benefits for the EV experience.

Why Lithium-Sulfur Matters to EVs

- Cheaper Production Costs: By using waste-derived sulfur and avoiding expensive materials, battery costs drop significantly.

- Improved Range and Efficiency: Higher energy density translates to more miles per charge.

- Faster Charging: Cutting charge time by half could make EVs much more convenient for drivers.

- Environmental Benefits: A sustainable supply chain reduces reliance on mining rare Earth materials.

Stellantis Lithium-Sulfur Battery Specs (Projected)

| Key Specifications | Details |

|---|---|

| Production Start Year | 2030 |

| Primary Materials | Unrefined sulfur, methane |

| Materials Avoided | Cobalt, nickel, manganese, graphite |

| Cost per kWh | Approximately 50% of lithium-ion cost |

| Energy Density | High gravimetric and volumetric |

| Charging Speed | 50% faster than lithium-ion batteries |

Stellantis’s groundbreaking venture promises to pave the way for a more accessible and efficient EV market globally. By marrying sustainability with innovation, the automaker reinforces its commitment to a greener, cost-effective future.